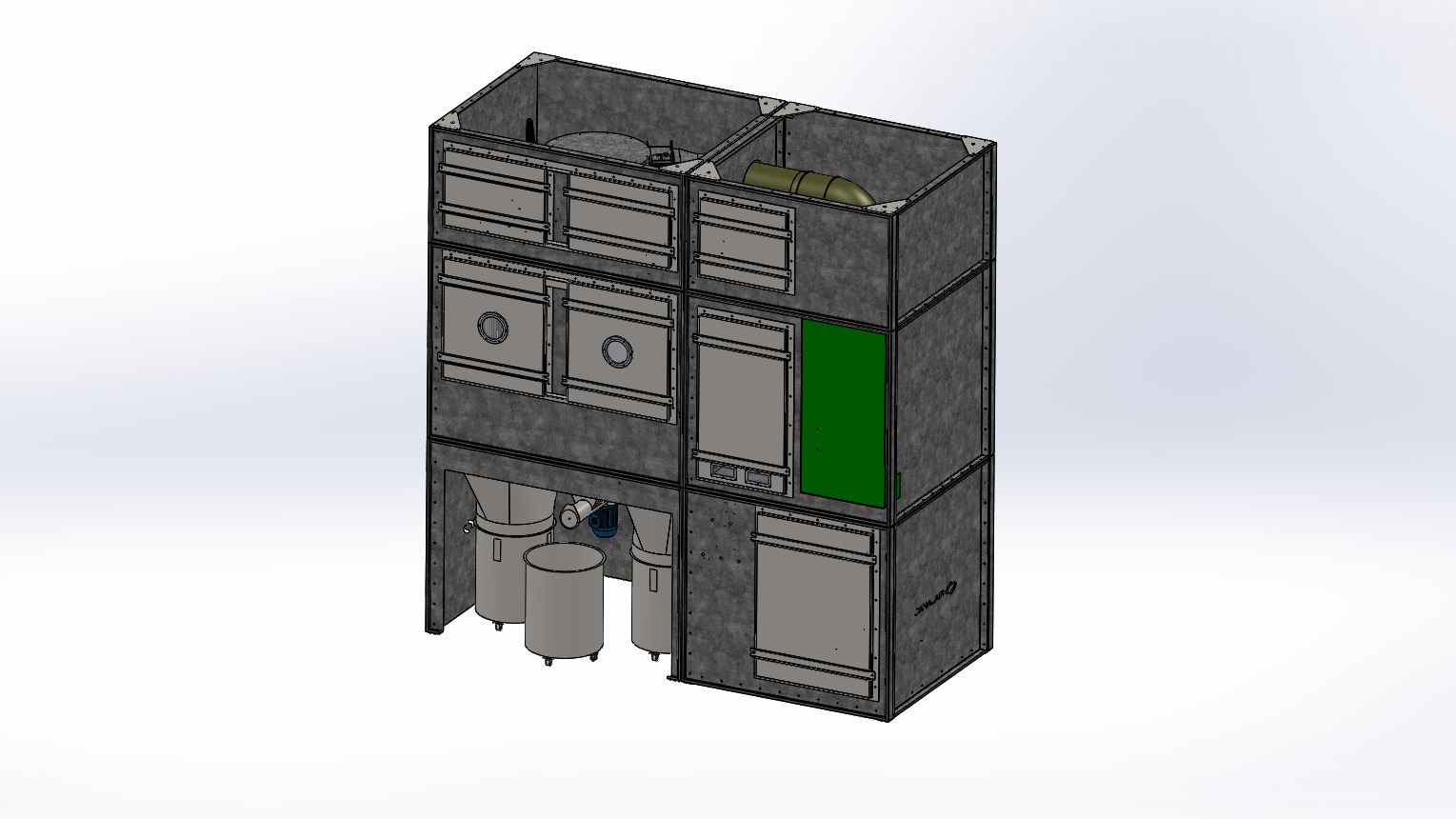

It is a compact module dedicated to all pre-separation and separation phases, with relevant storage of dust extracted from industrial processes.

The models available have flow rates from 5,000 to 10,000 m3/h.

This technology is particularly indicated to support cleaning systems on rewinders and spooling machinery.

Compact Separator can be totally integrated with Dual Blade℗ technology.

Strengths and Characteristics

- Abatement efficiency

- Limited dimension

- Adaptive system with limited pressure flotation at extraction inlet

- Self-cleaning system

- Easy maintenance

Operation

Air containing fibres and dust is extracted from production machines using the Compact Separator fan.

Following a first step, which blocks the heaviest material through a filtration set, the air extracted by the main fan enters the cyclone pre-separator. The latter separates the fibres, which deposit in the specific container beneath or (where planned) in the automatic screw unloader.

The air exiting the pre-separator, which only contains dust, enters the self-regenerating cartridge filtration stage with the help of compressed air.

The dust unloaded from the cartridges deposits in two containers beneath.

The filtered air exits the upper part of the Compact Separator.

Main parts

The system is composed of:

- Extractor fan

- First air-material separation stage

- Pre-filtering cyclone pre-separator for fibres

- Self-regenerating cartridge filtration

- Fibre collection container

- Screw for collection and unloading of fibres (where planned)

- Dust collection container

- Command and control electric box

- Second filtration stage (where planned)